When it comes to industrial equipment and enclosures, every component plays a role in reliability and safety. One such often-overlooked component is the galvanised piano hingea continuous hinge known for its durability, precision, and long-term strength. Across Australia, Schutts Industrial has established itself as a trusted supplier of industrial-grade hardware, including premium galvanised piano hinges designed for heavy-duty environments.

What Are Galvanised Piano Hinges?

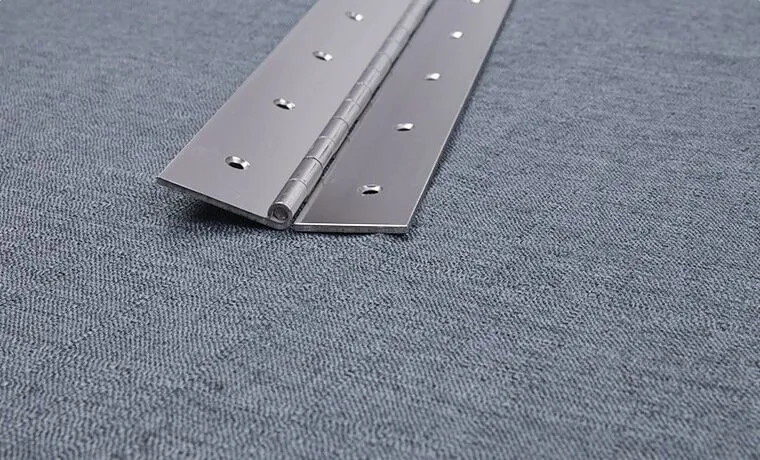

A galvanised piano hinge, also known as a continuous hinge, is a long, narrow hinge that runs the full length of the door, panel, or lid it supports. These hinges are typically made from steel and coated with a galvanised layer that prevents rust and corrosion. The galvanisation process involves applying a zinc coating that protects the underlying metal from environmental damage, making the hinge suitable for outdoor and high-moisture applications.

In industries where exposure to the elements is unavoidablesuch as construction, transport, or marine environmentsgalvanised hinges offer both strength and resistance to corrosion. The result is a smooth-operating, long-lasting mechanism that requires minimal maintenance.

Why Industrial Settings Rely on Galvanised Piano Hinges

Industrial environments demand hardware that performs consistently under stress. Unlike smaller, segmented hinges, a galvanised piano hinges distributes weight evenly across its entire length, reducing localized wear and extending the life of the assembly.

Key advantages include:

- Enhanced load distribution: Perfect for heavy panels, doors, and equipment lids.

- Improved durability: The galvanised coating resists rust and abrasion.

- Reduced maintenance: Long-lasting performance minimizes replacement costs.

- Precision alignment: Maintains stability and smooth motion over time.

For manufacturers and fabricators, using high-quality hinges means improved reliability and reduced downtimea priority in any industrial operation.

Schutts Industrial’s Quality Advantage

Schutts Industrial is recognized for supplying components that meet stringent industrial standards. Their galvanised piano hinges are built from robust materials, ensuring strength and resilience even in the harshest conditions. Each hinge undergoes quality checks to guarantee proper alignment, consistent coating thickness, and reliable motion.

Unlike mass-produced alternatives, the hinges from Schutts Industrial are crafted with precision and uniformity, ensuring a perfect fit and dependable performance. Whether used in machinery covers, access panels, toolboxes, or electrical enclosures, their hinges provide lasting value.

Applications Across Industries

The versatility of galvanised piano hinges makes them essential in a range of applications:

- Manufacturing: For equipment doors, safety guards, and machine enclosures.

- Transport and automotive: Ideal for vehicle doors, storage compartments, and utility boxes.

- Construction: Used in site cabinets, access hatches, and storage units.

- Marine and outdoor equipment: Perfect for exposure-prone environments requiring corrosion resistance.

- Electrical and HVAC industries: For access doors, panels, and protective housings.

Each of these industries relies on hardware that can withstand vibration, pressure, and weatheringrequirements that Schutts Industrial’s galvanised piano hinges meet with ease.

The Role of Galvanisation in Longevity

One of the most important aspects of hinge performance is surface protection. The galvanised coating acts as both a physical barrier and a sacrificial layermeaning it corrodes before the base metal does. This ensures that even if the surface is scratched, the zinc layer continues to protect the underlying steel from rust.

Schutts Industrial sources and supplies hinges with high-quality galvanisation, ensuring consistent coverage and superior corrosion protection. This makes their products ideal for demanding Australian environments where moisture, salt, and dust can quickly degrade untreated metals.

Customization and Technical Support

Every application has unique requirements. Schutts Industrial understands that hinge dimensions, thickness, and pin design can greatly influence performance. That’s why they offer a range of galvanised piano hinges in various sizes, lengths, and pin diametersalong with expert advice to help clients choose the right configuration.

Their technical team assists engineers and manufacturers in selecting hinges that align with their load, motion, and environmental specifications. This partnership approach ensures that customers receive components that perform efficiently and safely over time.

Conclusion

A galvanised piano hinge may seem like a small component, but its role in industrial machinery, enclosures, and equipment is vital. With superior corrosion resistance, strength, and precision, these hinges contribute to both operational efficiency and long-term cost savings.

As one of Australia’s leading suppliers, Schutts Industrial delivers reliable, high-quality galvanised piano hinges trusted by professionals across multiple industries. Their dedication to excellence, customization, and service ensures that every hinge supports performance, safety, and durabilityno matter the application.